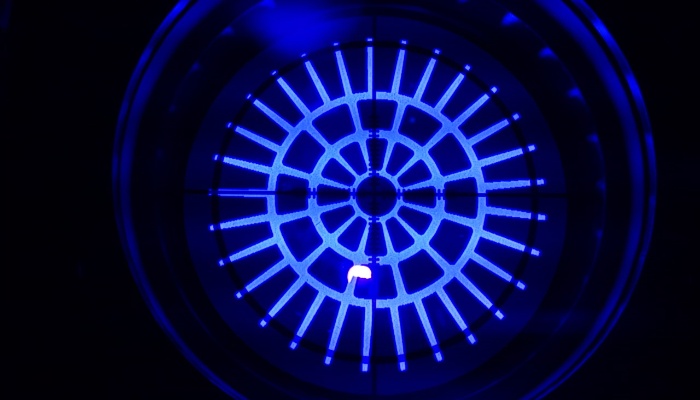

Redwire 3D printed turbine blisk/Image Source: Redwire Redwire , a new leader in mission critical space solutions and high reliability components for the next generation space economy, announced recently that its Ceramic Manufacturing Module (CMM) has successfully 3D printed a ceramic part in space for the first time.

.

The Ceramic Manufacturing Module, developed by Redwire’s subsidiary Made in Space for in-space manufacturing capability, successfully operated with full autonomy using additive Stereolithography (SLA) technology and pre-ceramic resins to manufacture a single-piece ceramic turbine blisk (a portmanteau of bladed disk) on orbit along with a series of material test coupons. The successful 3D printing of these test samples in space is an important milestone to demonstrate the proof-of-potential for Ceramic Manufacturing Module to produce ceramic parts that exceed the quality of turbine components made on Earth. The ceramic turbine blisk and test coupons will be stowed and returned to Earth […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments