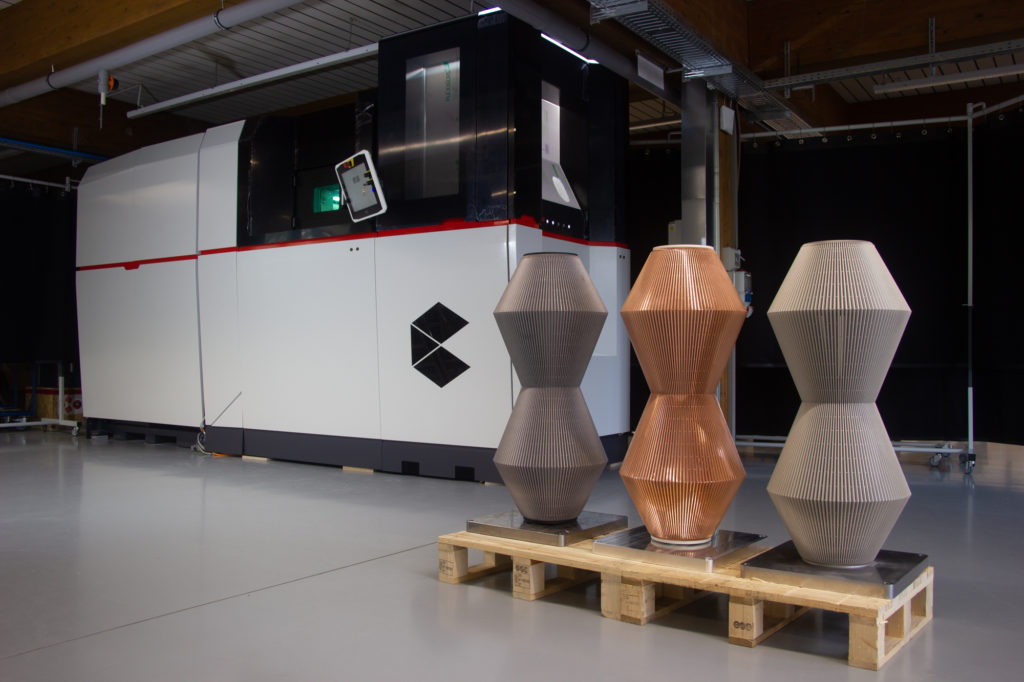

Florida-based Sintavia has expanded its metal 3D printing capabilities in order to grow its capacity for 3D printing rocket parts. The printers it has acquired are no ordinary metal 3D printing systems, but M4K-4 machines from AMCM in Germany. The 3D printers are modified versions of EOS M400-4 systems, more than double the height of the original EOS machine. Sintavia has purchased two more M4K-4 systems with which to 3D print rocket parts.

.

The company bills itself as “one of the largest rocket printers in North America,” having grown quite significantly in the past few years. In addition to developing a method for 3D printing aluminum and opening a new additive manufacturing facility , Sintavia acquired QC Laboratories to extend its testing of 3D printed parts. In 2018, it became the first company to receive approval for 3D printing parts for Honeywell Aerospace. Sintavia is the only company in the world with Nadcap approvals for laser additive manufacturing, electron beam additive manufacturing, and in-house heat treatment. (Image courtesy of Business Wire) All of this has been helped in part by investments from Japan’s Sumitomo Corporation, which most recently infused Sintavia with further funds in August 2020. The investment surely […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments